Architectural integration at the Lyon-Turin Tunnel

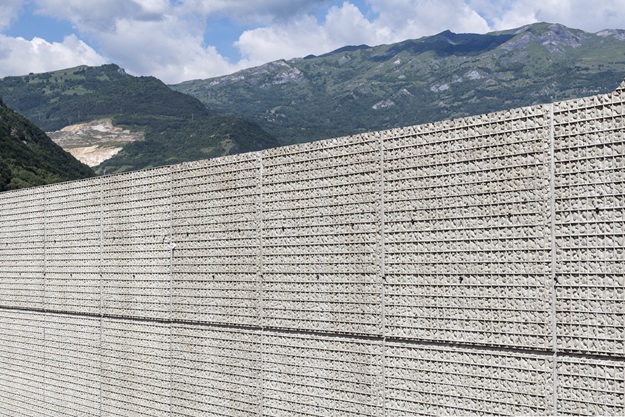

The Lyon-Turin Base Tunnel was being planned as far back as the early 1990s. The goal is to optimise the movement of goods between France and Italy and increase transport capacity. CO2 emissions would also be reduced. This would require a 57.5 km long tunnel through the Alps. The tunnel consists of two parallel tubes, each carrying a railway track. However, the high-speed link runs not only underground but also at surface level, for example, through the Saint-Jean-de-Maurienne Valley. This requires noise protection walls, roads, footpaths, bridges, station platforms and much more, all of which must be integrated into their surroundings. To ensure this was achieved, a Parisian architectural consultancy was commissioned to develop an architectural concept and determine the preferred material for the engineering structures. The designers decided in favour of concrete walls with a surface relief that gave them the appearance of gabions. These were to be created using formliners that were fixed into the formwork, which was then filled with concrete and stripped after the concrete had hardened. These types of formliners consist mostly of polyurethane and have a relief that lends the concrete the desired surface qualities. However, the architects had a problem: they could not find a formliner manufacturer that had such a design in its standard selection. It also turned out to be extremely difficult to find one that was in a position to design such a texture.

A new texture is realised

There are basically two methods for developing a new formliner texture: the first option is for the client to produce a digital 3D drawing and have the relief transferred onto a modelling board using a milling machine. This is then placed in a mould, which is filled with polyurethane to create the desired formliner. However, no such 3D drawing was available for the railway project. The second option is to make a real object, e.g. a coarse-grained wooden board, which is placed into the mould and polyurethane poured over it. This transfers the relief directly from the original. In the case of a gabion wall, however, this is not possible because the material poured over the original would flow into the voids. Therefore, it was difficult for the various potential suppliers to manufacture the desired formliner. Only NOE Betongestaltung GmbH was able to manufacture a suitable mould. NOE has worked for some time with an artist who continually comes up with designs for the company. For this project, he modelled a casting template, which was used to manufacture the formliner. After two years of development work, NOE succeeded in bringing a NOEplast texture to the market that produced a deceivingly realistic representation of the ribbed steel of a gabion basket and the individual stones in the wall. This product bears the name “Gabion”.

A texture for large areas

The new formliner measures 2.9 x 2.4 m and is 3.7 cm thick. It has no undercut features, with the result that it is easy to strip from the concrete. With the new formliner, extremely large surfaces can be created without visible joints or steps. This shows itself most impressively on a 15 x 10 m wall that the contractor constructed in one pour with NOE formliners. NOE supplied a total of 1,200 m² of formliners to the site. They were used to form 55,000 m² of concrete surfaces. This is possible only because the contractor was able to reuse the formliners about 40 times. However, this is nowhere near the reuse limit for NOEplast. Depending on the type of texture and external influences, NOEplast can be reused up to 100 times, which means it is extremely cost-effective.

A special service

NOE was not only able to manufacture the formliner, the company also made the work of the contractor much easier by performing a special service. NOE glued the formliners to a supporting board directly in the factory. The service is offered by very few manufacturers, but is gladly taken up by construction firms. It can be extraordinarily tricky to perform this task on site when faced with uneven ground and exposure to the weather. The formliners arrive on site attached to their supporting boards, which can be immediately mounted on the formwork panels. This is normally done by screwing them to the formwork facing from behind.

Ease of assessment

An important reason behind the designers’ preference for textured concrete walls rather than real gabions with a concrete wall behind them was the ease of future structural assessments. Since the railway line is used by a high-speed train service, the SNCF must regularly assess the structural capability of load-bearing and adjacent structures. A double-leaf wall construction would have made this task considerably more difficult. Therefore, constructing the walls with the desired surface relief and accepting that the manufacturer would first have to develop a new design was a much better solution for the client in the long term. NOE Betongestaltung was delighted to take on this task and, with the agreement of the architects and the commissioned artist, has now included this particular textured formliner in the company’s standard range. Other customers now have the opportunity to use the design for their construction projects. Since NOE has registered the design as a “Registered Design”, the company will be the only supplier of this texture to the market for quite some time. A great advantage to NOE, as the relief is already being received with great interest.